Profile of an occupation – textile production mechanic

In the spring of 2020, nearly one in two companies in the German textile and fashion industry became involved in helping to fill the gap in the supply of protective face coverings. By the end of April, production output had already reached 22 million masks a week and was still rising. One textile occupation is particularly crucial to the manufacture of the non-woven material that is required to make the masks – the textile production mechanic.

Technical textile products for numerous purposes

The items manufactured by textile production mechanics include high quality non-woven materials, fabrics and machine goods. These products are used in respirator masks, in dressing materials and bandages for the treatment and disinfection of wounds and in workwear and protective clothing. The materials must fulfil certain physical requirements and properties. Depending on the area in which they are deployed (as a simple protective measure or as a certified medical product), they will need to guard against liquids or bacteria or be resistant or impervious to germs. Other necessary characteristics might include breathability, vapour permeability, non-stickiness and absorbency.

Technical textiles are, however, also required in a large number of other areas. Airbags in vehicles, carbon fibres in aircraft fuselages, transparent membranes used on roofs, bristles in toothbrushes and textile-reinforced concrete are just some examples of typical products. Textiles or elements of textile fibres form an integral part of virtually every room, building or mode of transport. Technical textiles form the largest group of textile products. They account for over 40 percent of manufacturing capacity, a figure which is still rising. Home and household textiles and textiles used in clothing each make up 30 percent of production.

The textile production mechanics who manufacture all of these items mainly work in weaving mills, in spinning plants, in the knitted fabrics sector and in the non-wovens industry. Their tasks include the analysis of patterns, the setting up of production machines and plants, the monitoring of process sequences, the changing of product properties via the modification of process parameters and the performance of quality checks.

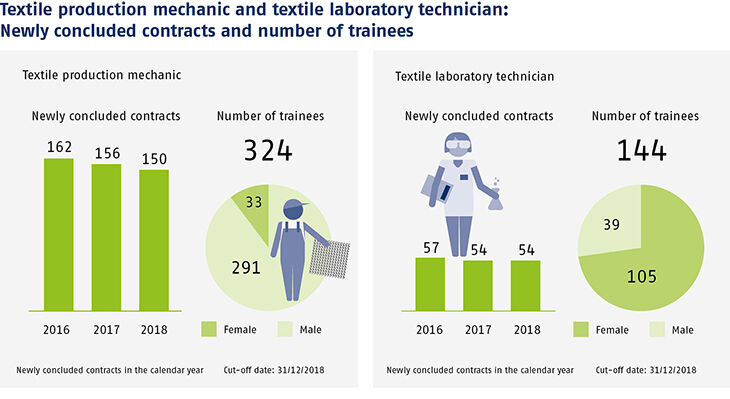

There are also further specialised occupations in the textile industry, such as textile laboratory technician. The job of a textile laboratory technician involves testing fibres, yarns and textile surfaces and the chemicals and auxiliary materials used in the manufacture and finishing of textiles in order to ensure that the materials and supplementary items processed by textile production mechanics are of the very highest quality. Whereas the occupation of textile production mechanic is largely the domain of young men, the proportion of female textile laboratory technicians is significantly higher (cf Figure).

Trends

The coronavirus pandemic has certainly led to a rise in demand for masks and personal protective clothing. But there are also many other products for which innovative technical textiles are increasingly being required. Fibres capable of conducting electricity can be woven into so-called “smart textiles”. Such fabrics can also contain organic and printed electronic components, micro processors or miniaturised textile-based sensors. These are able to react to certain bodily functions and generate relevant signals or emergency calls. This category also encompasses textile solar cells, photochromic textiles and textiles with electroluminescent properties.

In the area of medical textiles, we are seeing more and more fibre-based high-tech products in the form of stents or textile implants. Modern medical textiles integrate micro sensors and electrically conductive polymers into clothing. These can then be used for purposes such as monitoring the vital signs of patients and people in need of care.

Special term – fineness

The fineness of textile fibres and of other “linearly formed textile fabrics” such as yarns, threads and ribbons represents a measurement of thickness, diameter and strength. The smaller the diameter, the greater the degree of fineness will be. Compressibility and irregularity mean that diameters are difficult to determine. For this reason, definitions of textile fineness make reference to relationships between weight and length. In the case of sewing threads, for example, “Nm 40” means that 40 metres weigh one gram.

Career options

Numerous continuing training opportunities are available to textile production mechanics upon completion of initial vocational education and training. Certified industrial foreman in textiles and state certified technician specialised in textiles are just two of the qualifications that can be subsequently pursued. If the relevant entry requirements are fulfilled, it is also possible to proceed to a higher education course of study, such as a dual degree in “Textile and clothing technology”.

Digital learning platform

“textil+mode”, the Confederation of the German Textile and Fashion Industry, has joined forces with other project partners to develop a digital learning platform entitled Learn Textile! This provision is aimed at both employees and trainees and provides support in dealing with new materials and technologies. E-learning courses and practice and examination modules have also been created on the basis of target group-specific didactic concepts.

At a glance

- Last updated: 2005

- Duration of training: 3 years

- Responsibility: trade and industry

- Training structure: Mono occupation

- DQR reference level: 4

- BIBB website page on the occupation: www.bibb.de/de/berufeinfo.php/profile/apprenticeship/zu67zugj

- textil + mode, Confederation of the German Textile and Fashion Industry: https://textil-mode.de/en

- Learn textile! Learning platform: https://learn-textile.de

- Training campaign for textiles, clothing and fashion: www.go-textile.de

All links retrieved: 30.09.2020

(Compiled by Arne Schambeck)

Translation from the German original (published in BWP 3/2020): Martin Kelsey, GlobalSprachTeam, Berlin