Profile of an occupation – Packaging materials technologist

As e-commerce continues to flourish, more and more types of packaging are needed for a countless assortment of products ranging from chocolates to fridges. In 2018, the German folding box industry alone reported a production volume of 870,971 tonnes. But who is responsible for manufacturing all these different packaging materials, for ensuring that each product has the right packaging to protect it and for doing all of this in a way which conserves resources?

Developing and manufacturing packaging

The titles of predecessor occupations provide a vivid idea of the tasks of the past. In the 1930s and 1940s, there were bag makers, machine bag makers, cardboard packaging makers and folding box makers. Bag machine operator was added in 1951. These functions were amalgamated for the first time in 1964, when the occupation of packaging mechanic came into being. The designation of packaging materials technologist was introduced following modernisation of the training occupation in 2011. A further revision took place in 2018, but this time only the regulations relating to the final examination were amended.

Packaging materials technologists manufacture various kinds of packaging made of paper, cardboard and plastic. They also develop packaging solutions with the assistance of CAD programmes, make prototypes and plan production procedures. For this purpose, they need to select materials and manufacturing processes and operate production plants. They monitor and optimise the manufacturing process, carry out quality assurance measures and use control and process control systems. Packaging materials technologists work at industrial companies in the paper and plastics manufacturing sector and for supplier firms.

Trends

Digitalisation is also changing tasks in the packaging sector. Innovative technologies including artificial intelligence are creating new opportunities in the development and production of packaging materials but are also increasing skills requirements.

Intelligent packaging

Skilled workers in the packaging industry are becoming increasingly involved with “smart packaging”. Further packaging functionalities are gaining in significance alongside its protective purpose. Integrated sensors and codings, for example, allow smart packaging to document the route taken through the delivery chain. It can also provide information on damage to cargo caused by excessive vibrations, report on any changes to foodstuffs and ensure the genuineness of the products that have been packaged in sectors such as the pharmaceutical industry.

Learning in a virtual environment

The digitalisation of production processes, embedded systems and the Internet of Things are all making tools and production machines more complex and more difficult to operate and programme. Trainees are increasingly learning within a virtual environment. Methods here include training courses which link machine control systems with virtual models, e-learning programmes and the use of VR data goggles. These approaches enable them to master the operation of new machine elements without consuming materials or causing wear and tear to tools. They can also, for example, learn how to use a new type of machine before such equipment is available at the company.

Special Term: Calendering

In the elective qualification of “Finishing technology”, trainees learn how to control refining techniques, particularly with regard to embossments, print designs, lacquer coatings, calendering and perforations.

Calendering involves improving surface properties such as lustre and smoothness whilst also reducing the thickness of the material. Paper is passed through several heated and polished steel rollers which have been arranged consecutively. Various effects can be achieved by varying pressure, temperature and the speed at which the rollers move.

Career and options

Trainees who have already completed a two-year programme of vocational education and training in the occupation of machine and plant operator specialising in print production can obtain full credit transfer for this period of learning. Specialisations such as die making can be pursued during and after training via continuing training courses.

Typical advanced training programmes in the packaging industry lead to the qualification of certified industrial supervisor specialising in paper production, print media or paper and plastics processing. These are aligned to reference level 6 of the Deutsche Qualifikationsrahmen (DQR) [German Qualifications Framework]. Paper Technology Engineering is one example of the degree courses of study that may be completed at a university of applied sciences.

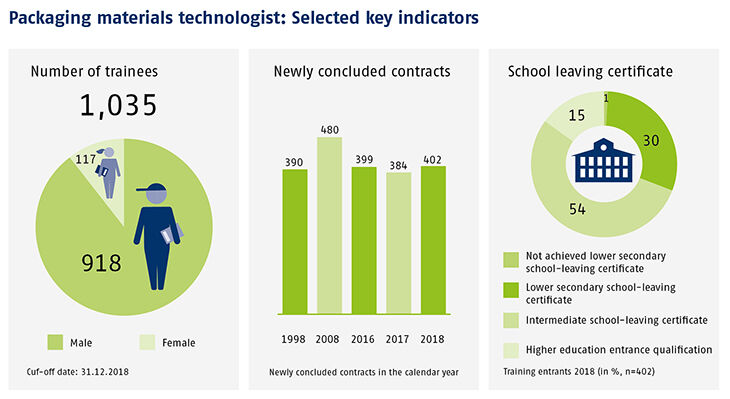

At a glance

- Last updated: 2018

- Duration of training: 3 years

- Responsibility: trade and industry

- Training structure: occupation with elective qualifications

- DQR reference level: 4

- BIBB website page on the occupation: www.bibb.de/de/berufeinfo.php/profile/apprenticeship/4714784

- Brochure published by the Zentral-Fachausschuss Berufsbildung Druck und Medien (ZFA) [Central Committee for Vocational Education and Training in Print and Media] www.zfamedien.de/downloads/Packmitteltechnologe/Grundlagen/Packmitteltechnologe_ZFA.pd

(Compiled by Arne Schambeck)

Sources: Hauptverband Papier- und Kunststoffverarbeitung e.V. [Main Association of the Paper and Plastics Manufacturing Industry], Fachverband Faltschachtel-Industrie [Association of the Folding Box Industry], “Berufenet” Portal of the Bundesagentur für Arbeit [Federal Employment Agency]

Translation from the German original (published in BWP 1/2020): Martin Kelsey, GlobalSprachTeam, Berlin