Profile of an occupation – pharmaceutical technician

Pharmaceutical technicians control plants which produce tablets, ointments, powders and vaccines. The manufacture of vaccines is a complex and sensitive process which requires a particularly high degree of responsibility. This profile also presents trends which may expand the spectrum of tasks in future.

Production of vaccines

Suitable medicines and vaccines are essential building blocks for overcoming the coronavirus pandemic. Following rapid global research, the focus has now shifted to vaccine production. Requirements in respect of quality and safety are extremely high. Pharmaceutical technicians have a major role to play within this process. They take charge of the whole of the product manufacturing procedure at pharmaceutical companies. This responsibility includes weighing active and added ingredients, monitoring the actual production process itself and taking care of packaging. It also extends to encompass quality management. Germany has up until now focused on vaccines to combat flu, tick-borne encephalitis, diphtheria, Ebola, whooping cough and rabies. The manufacturing process is often lengthy. Up to 500 individual stages are involved in the case of some vaccines. The number of quality checks and tests required may be even higher. This serves to highlight the strong sense of responsibility that pharmaceutical technicians need to possess alongside a high degree of precision and care.

Special term – Galenics

Galenics refers to the principles of compounding, preparing and manufacturing medicines. It is a pharmaceutical designation named for the Greek physician Galen, who lived in the 2nd century BC and also produced pharmaceutical writings. This traditional term is still used today. One elective qualification in the training regulations is, for example, entitled “Galenics for semi-solid and liquid dosage forms”.

Proportion of women exceeds 50 percent

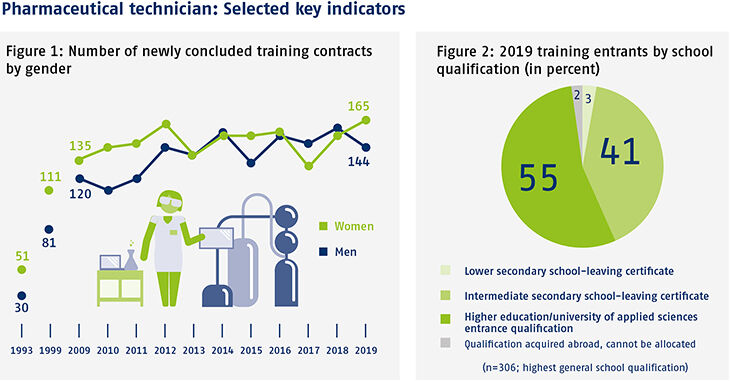

The proportion of female pharmaceutical technicians is high for an industrial manufacturing occupation. In 2019, 165 out of a total of 309 new training contracts were concluded with female trainees. This represents a proportion of 53 percent. Newly concluded contracts have been recorded by gender since 1993. These statistics reveal that females have traditionally made up the majority of trainees in the occupation. Male trainees have only begun to catch up over the past six years (cf. Figure 1). By way of comparison, the proportion of females in the training occupation of chemical technician, a similar manufacturing occupation in the chemical industry, is significantly lower. The figure for 2019 was just over 16 percent. The high level of prior learning amongst pharmaceutical technicians is conspicuous. In 2019, 55 percent of training entrants were in possession of a higher education or university of applied sciences entrance qualification (cf. Figure 2).

Trends

Ongoing digitalisation is also changing the task areas and requirements profiles of pharmaceutical technicians. They are increasingly moving away from their status as “machine operators” and are becoming “process specialists”. Highly automated procedures are required in order to avoid production errors and contamination. This means that there is a demand for skilled workers who are able to offer a deeper understanding of production plants and processes. Pharmaceutical technicians are now more involved with controlling networked manufacturing systems, which monitor sequences with the aims of driving forward automation and facilitating the autonomous analysis of data.

3D printing

3D printing is a technology which may bring about a sustained change in the way that medicines are manufactured in future. The first tablet to be entirely produced via a 3D printing process has already gained approval in the USA. Scientists in Germany are carrying out research into suitable procedures for the pharmaceutical industry. The main benefits lie in the individualisation of medical products, i.e. dosage in line with patient needs and the ability to produce batch sizes containing relatively few tablets for purposes such as carrying out active ingredient trials. Individual scalability of active and added ingredients can, for example, be used to adjust the concentration within a tablet in a continuously variable way.

Smart packaging

Near-field communication chips and QR codes, which can be used to obtain additional information via smart phone, are both examples of “smart packaging”. Packaging equipped with storage chips, integrated displays and operating elements is seen as offering great potential. Such forms of packaging can use acoustic and visual signals to remind patients to take their medicines regularly or to order repeat prescriptions in time. Smart packaging can also communicate with the packaging machine during the production process. The packaging can, for example, tell the plant which content should be inserted via a data matrix code.

At a glance

- Last update: 2009

- Duration of training: 3.5 years

- Responsibility: Trade and industry

- Training structure: Training occupation with elective qualifications

- DQR reference level: 4

- BIBB website page on the occupation

- Video on the training occupation

(Compiled by Arne Schambeck)

Sources: Pharma Fakten e.V., Association of Researching Pharmaceutical Manufacturers, Federal Employment Agency, German Pharmaceutical Industry Association

Translation from the German original (published in BWP 1/2021): Martin Kelsey, GlobalSprachTeam, Berlin